Traverse City Products

Traverse City ProductsRequest A Quote

Traverse City, MIAt Traverse City Products, we specialize in the precision and versatility of roll forming, offering an extensive range of products and services designed to meet the diverse needs of our clients. With years of experience in the industry, we take pride in our ability to create custom profiles that not only match the most demanding specifications but also ensure the highest level of quality and consistency. Our capabilities in roll forming allow us to work with a variety of metals, including steel, aluminum, and other alloys, to create intricate shapes that are both functional and aesthetically pleasing. We utilize state-of-the-art equipment and innovative techniques, which enable us to efficiently produce components for industries such as automotive, construction, and manufacturing. From simple designs to more complex, multi-stage processes, we possess the flexibility to handle orders of all sizes, whether small batches or large production runs. We understand the importance of precision and durability in the products we deliver, and we are committed to meeting our customers' needs through every stage of production. Our team of engineers works closely with clients to develop tailored solutions, ensuring that each product meets not only the required specifications but also the specific performance criteria. With a focus on quality control and customer satisfaction, we provide services that include not only roll forming but also a variety of secondary operations such as cutting, punching, and welding, further enhancing the functionality of the finished products. By offering both standard and custom roll-formed products, Traverse City Products is proud to be a trusted partner in industries where precision and reliability are paramount. Our experience, combined with our commitment to innovation, enables us to stay at the forefront of the roll forming industry, continuously evolving to meet the ever-changing demands of our clients.

Leading Roll formed Parts Companies

More Roll formed Parts Companies

Additional Categories: Blowers, Blow Molding, Rubber To Metal Bonding

Cold Headed Parts

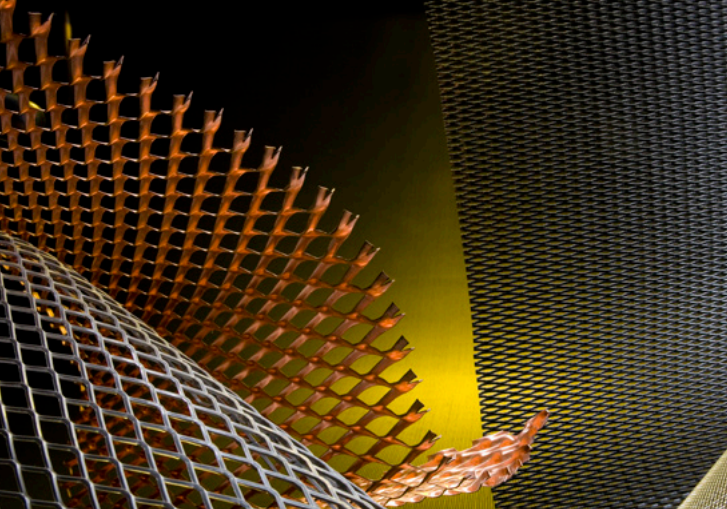

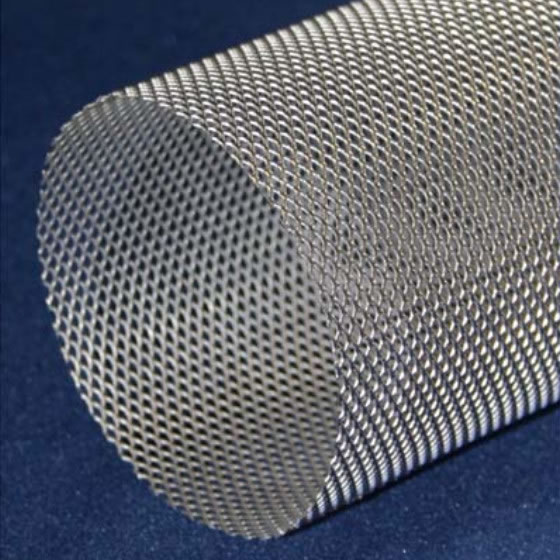

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services