Roll formers are machines that perform roll forming procedures of metals. Roll formers can also be defined as the companies that perform roll forming procedures. A long strip of metal, typically in a coil shape, is the first step in this distinctive metal-forming procedure. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

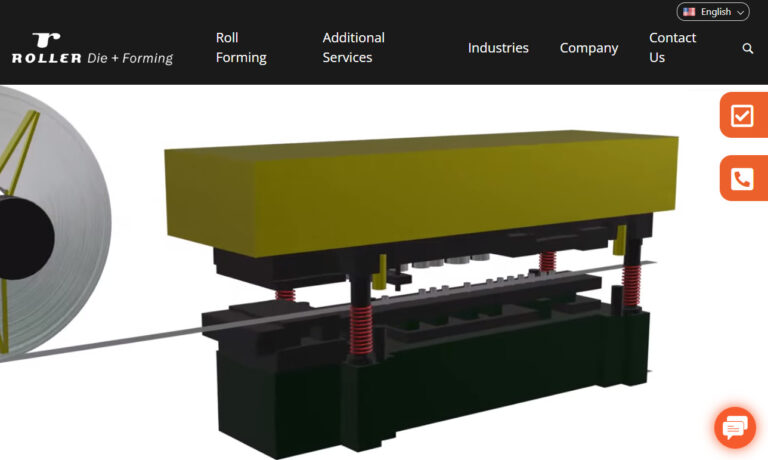

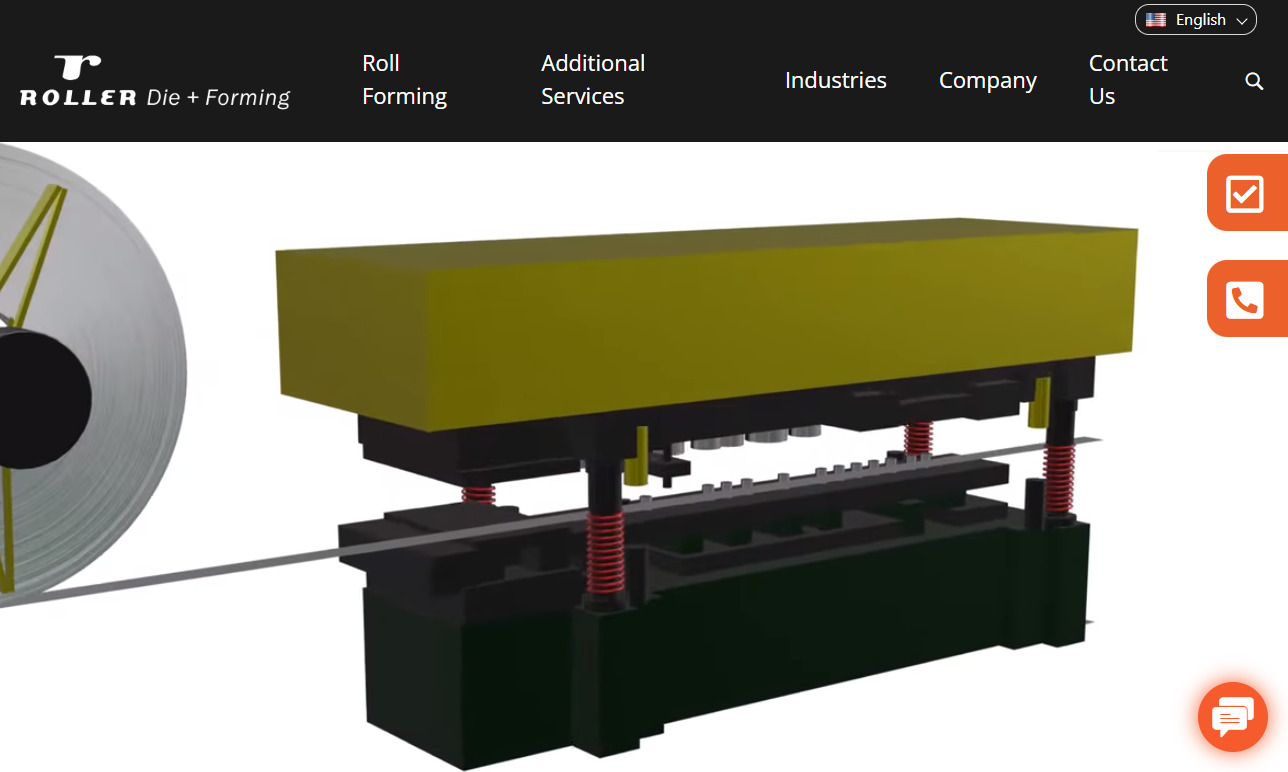

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Roll Former Companies

What are Roll Formers?

To produce a homogeneous shape, a roll forming machine pushes material through a number of mated tool dies. The workpiece is gradually bent throughout each phase of the process until it takes on the desired shape. The metal is turned, pulled, and pushed with each pass. The product is chopped to length by a machine; then, the roll forming manufacturer labels and packages it on a runoff table.

Rollers are expertly created with a flower pattern that shows the metal strip's successive modifications. Each roller's shape comprises the flower pattern's portions. Roll forming is simulated using CAD or CAM renderings so that any mistakes or faults can be fixed before manufacturing. Engineers can choose calibrations and profiles for folding or bending angles using software tools to generate new geometries by clicking their mouse.

Roll Forming Process

In traditional stamping, the complete portion is created at once. When the forces from forming surpass what the metal can withstand before splitting, the component shape is limited, especially how complicated it can be. Only a little area of a roll-formed part is ever bent since, even here, only a small amount of forming strain is applied to the part during each station. As a result, properly designed roll forming processes can produce more complicated shapes.

A coil or several lengthy strips are passed through a roll forming line during the forming process, transforming the flat sheet into a contoured cross-sectional profile. The distinctive feature of this method is the employment of succeeding forming stations, each of which moves the metal in the direction of the desired shape.

A computer designs the track and determines the best location and form for the rollers based on the desired profile. More rollers are used as the desired form becomes more sophisticated. The roll forming line can bend metal, form it into tubes, build metal structures that resemble mazes, and punch holes in the metal.

Precision-contoured metal rollers shape the incoming sheet metal. They frequently double as rollers with motorized drives that draw the strip through the roll forming machine. The geometries of these rollers can be as straightforward as the cylindrical rollers used to push bags through airport scanners, or they can be much more complex. After the last station of forming, the strip is sheared to the desired length for the finished product.

Types of Roll Formers

The different types of roll formers include:

Wrap Roll Forming

In wrap roll forming, roll forming machines create rated L-shaped edges or flanges on sheets of metal. Wrappers resemble large dining tables with a set of rollers running the table's length. They can produce both basic and complex flanges at speeds of fifty feet (15 m) per minute.

Beam Roll Forming

Box beams for construction are made using beam roll forming. The plans result in beam profiles with flutes for floor framing and decking. High tensile strength steel is used to make beams, including single thickness webbing and double thickness flanges for added strength.

Stud and Track Roll Forming

Stud and track machines make assembly frames for sturdy, lightweight partitions that can be up to 32 feet (9.75 m) long with a variety of thicknesses.

Angle Roll Forming

The most fundamental of the roll formed profiles, equilateral or uneven perpendicular angles, are manufactured by angle roll forming machines using high tensile strength steel. Roll formed angles are mostly used for framing, although they can also be used for rails, posts, supports, and brackets.

Seamless Roll Forming

The production of rectangular, square, oblong, and circular tubing is the main application for seamless roll forming. A rolled tube is joined together using the TIG process at the conclusion of the roll forming procedure, as shown in the diagram. Tubing is manufactured from various ferrous and non-ferrous metals, just like many roll-formed items.

Choosing the Proper Roll Former Manufacturer

To make sure you have the most productive outcome when purchasing roll formers from a roll former manufacturer, it is important to compare at least 5 companies using our list of roll former manufacturers. Each roll former manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each roll former business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple roll former businesses with the same message.

Cold Headed Parts

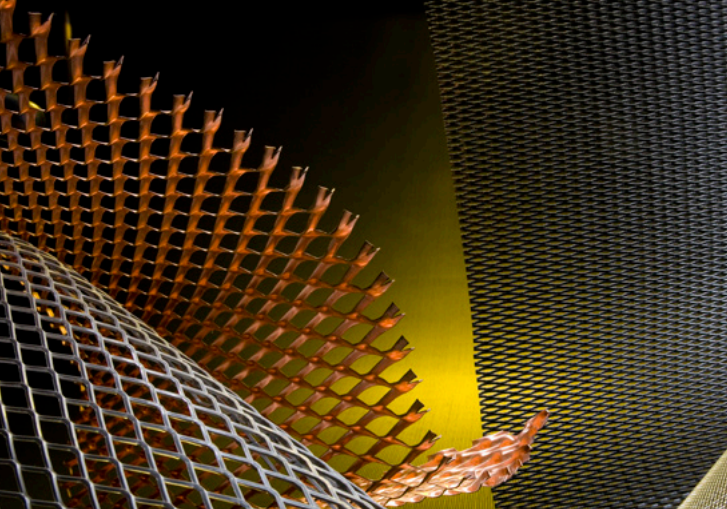

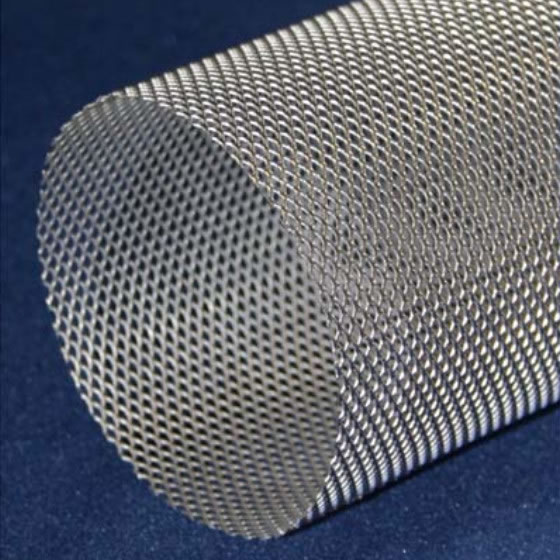

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services